The American-Made Challenges: Solar Desalination Prize is a four-stage competition designed to accelerate the development of low-cost desalination systems that use solar-thermal power to produce clean water from salt water. Competitors receive cash prizes as they advance through each stage, culminating in a $1 million grand prize for the successful testing and demonstration of a promising solar-thermal desalination system prototype.

Round 1 of the prize was announced September 23, 2019, and launched April 28, 2020. Participants from private companies, nonprofit organizations, academic institutions, students, and national laboratories submitted their ideas for a solar-thermal desalination component or system prototype, along with a pathway to commercialization.

On October 19, 2020, 19 quarterfinalists from 12 states were selected to advance to the second competition phase. These competitors received $50,000 in cash and will form a team and refine plans for a fully operating solar-thermal desalination system.

On April 12, 2021, eight semifinalists from six states were selected to advance to the third competition phase. These teams received $250,000 in cash and a $100,000 voucher that can be redeemed at a national laboratory and/or qualified partner facilities to design their systems. While they’re completing detailed designs of their systems in the third phase, teams must also obtain the permitting and approval documentation necessary to build them.

On February 28, 2023, one finalist was selected to advance to the fourth and final competition phase. This team received a cash prize of $750,000 and another $100,000 voucher. The team will then build its systems, demonstrate the operation, and validate key performance metrics.

Prize competitors have three years to submit their prototype system to compete for the $1 million grand prize. Submissions will be evaluated every second Monday in April, starting in 2022. Winners will be determined approximately one month after visits to their newly built system sites.

Finalist

Katz Water Technologies: Solar Thermal Desalination System at a New Mexico Oil Site

Location: Houston, Texas

Project Summary: Katz Water Technologies is redesigning its self-contained, compact distillation system to use solar-thermal energy instead of natural gas. The new design blends the existing multi-stage thermal distillation technology into a simpler design with the multistage process occurring in a single closed-loop heat exchanger. The technology has the potential to be a modular, portable system that can supply fresh water where needed. Prototype site testing is being planned at the Bureau of Reclamation’s Brackish Groundwater National Desalination Research Facility, with a particular focus on the oil and gas production market.

Semi-Finalists

BrineZero: Brine Concentration with Managed Salt Precipitates

Location: Hopewell, New Jersey

Project Summary: This team, led by AIL Research, is developing a membrane desalination system capable of handling very-high-salinity water and using recovered heat to preheat the brine feed. The system will be designed to pre-crystallize readily precipitating ions, such as magnesium and calcium, before the brine contacts the membrane, to prolong membrane lifetime. Managing the precipitation of salt and using recovered heat allows more water recovery from high-salinity brines. The team will focus their technology on the production of agricultural water for regions of the country where brackish groundwater is too saline to be used directly. They plan to install their prototype at Bell Ranch in California, in partnership with Global Water Innovations.

Connecticut Center for Applied Separations Technology: Membrane Distillation with Ceramic Membranes

Location: Storrs, Connecticut

Project Summary: This team, led by researchers from the University of Connecticut, will integrate a newly developed ceramic membrane technology with a solar collector system to treat high-salinity or chemically complex brines. The ceramic membranes provide thermal and chemical stability that enable them to process challenging saline waters, operate at higher temperatures than existing polymeric membranes, and be more aggressively cleaned when fouled by scaling salts and organics. The team will be developing their pilot for deployment at the Kay Bailey Hutchison Water Treatment Plant in El Paso, Texas.

Espiku: Selective Condensation and Evaporation Using Precise Temperature Regulation (SCEPTER)

Location: Corvallis, Oregon

Project Summary: This team plans to advance and commercialize technology developed at Oregon State University and Michigan State University plans to advance a humidification-dehumidification process that can recover clean water from water produced by oil and gas extraction. A novel cyclone separator, which can be easily designed at small scale for portability, separates salt from humid air and enables the process. By separating humid air from solid salt particles, this technology could be a cost-effective method to achieve zero-liquid discharge. The team will design their pilot to be installed at the Bureau of Reclamation’s Brackish Groundwater National Desalination Research Facility.

GreenBlu: Zero Discharge Multi-effect Adsorption Distiller

Location: Trenton, New Jersey

Project Summary: GreenBlu will develop a prototype plant of a zero-liquid discharge solar-thermal desalination system with mineral recovery using its multi-effect adsorption distillation technology. The concept has the potential to be much more thermally efficient, and require simpler operation and maintenance, relative to conventional distillation technology. This team has forged partnerships with key vendors and will be utilizing a solar collector field developed by Hyperlight, in Brawley, California, to host their pilot.

Katz Water Technologies: X-VAP—Self-Contained Distillation

Location: Houston, Texas

Project Summary: Katz Water Technologies is redesigning its self-contained, compact distillation system to use solar-thermal energy instead of natural gas. The new design blends the existing multi-stage thermal distillation technology into a simpler design with the multistage process occurring in a single closed-loop heat exchanger. The technology has the potential to be a modular, portable system that can supply fresh water where needed. Prototype site testing is being planned at the Bureau of Reclamation’s Brackish Groundwater National Desalination Research Facility, with a particular focus on the oil and gas production market.

Solar Desalt: Sorption-Based ZLD Technology

Location: Houghton, Michigan

Project Summary: Researchers from Oak Ridge National Laboratory and Michigan Technological University are integrating standard multiple-effect desalination system (MED) technology with a high-temperature desorption process and a low-temperature crystallization process to achieve zero liquid discharge (ZLD). They have identified a liquid that could extract all the water-vapor volume from the brine slurry of a MED system, thus enabling an energy-efficient, modular ZLD treatment. The team has selected a test site in Arizona provided by the solar collector supplier Rackam and is collaborating with a wastewater treatment plant as a potential customer for the produced desalinated water.

STREED - Resonant Energy Exchange Desalination

Location: Houston, Texas

Project Summary: A team led by researchers from Rice University has developed a nanoparticle-based high-efficiency, low-maintenance solar-heated membrane distillation technology. The team will design a prototype of their nanophotonics solar absorber desalination system in combination with thermal energy storage. The team plans to develop a scalable system design that uses spiral-wound architecture to minimize the plant’s physical footprint, which will be located at either the Bureau of Reclamation’s Brackish Groundwater National Desalination Research Facility or a development near Corpus Christi, Texas, to provide fresh water.

The Hard Ion Team: Switchable Solvent Water Extraction from Brine

Location: Rohnert Park, California

Project Summary: A team including researchers from Idaho National Laboratory and Trevi Systems is developing a solar-thermal-powered liquid/liquid extraction process that removes “hard” ions, like calcium and magnesium, before brine is treated by reverse osmosis, a conventional desalination process. This method could significantly improve the efficiency of reverse osmosis by allowing the process to operate over wider brine input conditions and requiring less maintenance to remove the scale caused by hard ions. The team has formed partnerships with Idaho National Labs, Artic Solar, and Global Water Innovation to develop and test their prototype at Bell Ranch in California, to target the agricultural water market.

Quarterfinalists

CCR’s LTDis Technology

Location: Frisco, Texas

Project Summary: Crystal Clearwater Resources is developing its “LTDis” evaporator technology, which can use solar heat to treat challenging waste streams and achieve zero liquid discharge. The concept uses a spray-based evaporation and condensation chamber to replace the stages with tubes (surfaces used for condensation and evaporation) in conventional multiple-effect desalination plants. Direct evaporation and condensation of sprays in vacuum chambers eliminate corrosion concerns and reduce the size and cost of vessels.

Forward Osmosis – Biomimicry at Work

Location: Rohnert Park, California

Project Summary: This team of researchers from the Natural Energy Laboratory of Hawaii and Trevi Systems, a small company developing novel forward osmosis (FO) desalination technology, proposes to build a 500 m3/day FO system with solar collectors as a heat source. The team will advance its FO draw solution by significantly increasing throughput and lowering the system’s energy requirements.

Heat Storage for 24-Hour Solar Desalination

Location: Arcadia, California

Project Summary: Element 16 is a small company developing a sulfur-based thermal energy storage (TES) technology to generate low-pressure steam for desalination. Sulfur has a low melting point (105° Celsius) and low cost ($80/ton). By using lower-cost containment materials, this project aims to reduce sulfur TES cost to below $15/per kilowatt-thermal and reduce heat-exchanger costs, to attain a levelized cost of water below $0.50 per cubic meter (m3).

Mimicking Rain Cycle Using Traveling Liquid Beads

Location: Los Angeles, California

Project Summary: This team, led by researchers from the University of California, Los Angeles, is developing a humidification-dehumidification process that lowers the cost of manufacturing high-surface-area components. By using low-cost polymer string architectures in the dehumidification process, the team expects cost-effective, energy-efficient desalination of high-salinity water.

Modular Inexpensive Solar-Thermal Evaporative Desal

Location: Andover, Massachusetts

Project Summary: Physical Sciences Inc. proposes to integrate a low-concentration solar receiver with a multistage flash evaporator in one device to reduce capital cost. The evaporator efficiently distills water by combining numerous distillation stages so that each one uses the heat output from the previous stage. The evaporator operates at low temperature, which allows the use of low-cost cylindrical optics. The team intends to build a 20-stage multistage flash device inside a cylindrical tube receiver to produce 100 m3/day of desalinated water.

NoAir: Super-Vacuum Gap NanoMembrane Distillation

Location: Gainesville, Florida

Project Summary: This team, led by the small company Focused Sun, proposes a linear Fresnel solar-collector system that will generate steam for a process called thermal vapor compression (TVC) to provide pumping power for the system. The brine will be preheated by a membrane desalination (MD) system, which is then fed with brine from the TVC system to further desalt and recover water. This MD-TVC system could attain high energy efficiency at low pressure and be used to treat water produced from oil and gas extraction, with no electricity input.

Solar Aqua Flex: Off-Grid Solar Still

Location: Nashville, Tennessee

Project Summary: This team, led by researchers from Vanderbilt University, will develop a multistage membrane distillation system made of floating, flexible, layered “mats” to desalinate water. The mat has a nonporous, heat-absorbing top layer; a water layer that evaporates; a distillate layer where the vapor ends up after moving through a membrane to condense; a feedwater layer; and a conductive layer that heats the feedwater. This concept has the potential to be modular and portable, with higher production than similar existing systems.

Solar Thermal Enhanced Evaporation

Location: Minneapolis, Minnesota

Project Summary: Researchers from the University of Minnesota propose a humidification-dehumidification desalination system that will handle small-volume brine from industrial facilities that do work such as electroplating, which coats metal onto surfaces, dyeing, and mining. This project will use large fans, evaporators, and heat-pump-driven condensation systems to manage brine mixed with industrial metals. The team plans to industrially source forced-flow evaporators and fans to attain a levelized cost of water no higher than $1/m3.

TSSE Desalination of Hypersaline Brines

Location: Santa Barbara, California

Project Summary: A Columbia University-led team proposes a desalination technique using a solvent that, when heated, attracts brine in high-salinity water, separating it from fresh water. Increasing the temperature of the feedwater will cause the clean water to float above the solvent, enabling reuse of the solvent in subsequent cycles. This method has the potential to be highly thermally efficient because it does not require evaporation and condensation, unlike in conventional desalination systems.

Urban Solar-Desal Building

Location: College Park, Maryland

Project Summary: A team led by the University of Maryland’s Center for Energy Environmental Engineering will develop a vertical, building-integrated desalination system for urban areas. Solar-thermal collectors will be the energy source to heat multistage vacuum membranes in the system. This concept has the potential to decentralize desalination at the point of use.

100% Solar Transcritical Water Desalination

Location: Pittsburgh, Pennsylvania

Project Summary: Epiphany Solar Water Systems has developed a water desalination and crystallizer unit that uses solar-thermal energy to desalinate water by increasing the temperature and pressure sufficiently to cause water to transition to a supercritical phase, in which salt does not dissolve. The fully integrated system will use solar collectors to provide heat, heat recovery from the supercritical water distillate to improve efficiency, and crystallizers to separate salts from the distillate. This technology has the potential to be more thermally efficient than conventional distillation techniques.

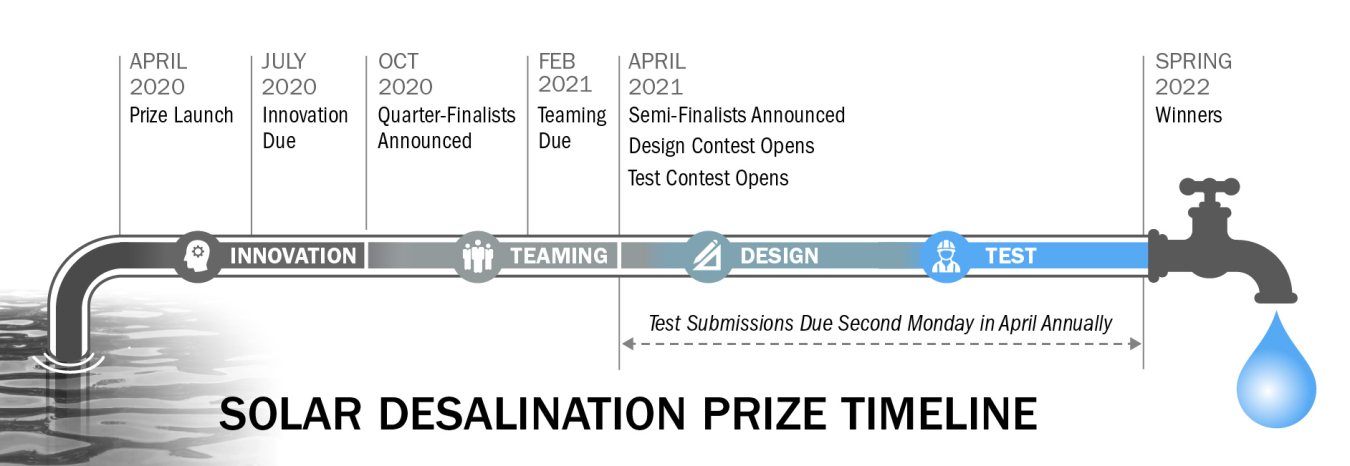

Timeline

- Innovation: The first phase opened April 28, 2020, and closed July 16, 2020. Competitors were announced October 19, 2020.

- Teaming: The second phase opened October 19, 2020, and closed February 9, 2021. Teams were announced April 12, 2021.

- Design: The third phase opened April 12, 2021, and will close when competitors have completed their designs and obtained the required documents, no later than April 2024.

- Test: The fourth phase also opens on April 12, 2021. Finalists will have three years to submit their prototype system to compete for the Test prize. Test prize submissions will be evaluated every second Monday in April, starting in 2022. Winners will be determined approximately one month after visits to their newly built system sites.

Learn More

- Visit the Solar Desalination Prize website for details on the competition.

- Learn more about Round 2 of the competition.

- Join the American-Made Network.

- Watch a recording of the June 18, 2020 webinar that explains how the competition works.

- For questions about the Solar Desalination Prize, email challenge@nrel.gov.

The Solar Desalination Prize is administered by the National Renewable Energy Laboratory and is part of the American-Made Challenges.